The Future of Membrane Switch Technology in the Automotive Industry

The Future of Membrane Switch Technology in the Automotive Industry

Blog Article

Membrane Layer Change Modern Technology: The Key to Trusted and Economical Interfaces

Membrane layer switch innovation has actually arised as a pivotal part in the design of customer interfaces, providing both reliability and cost-effectiveness across a diverse range of applications. As we explore the diverse benefits of membrane layer buttons, their possibility for technology elevates concerns regarding future applications and developing patterns.

Recognizing Membrane Layer Switch Innovation

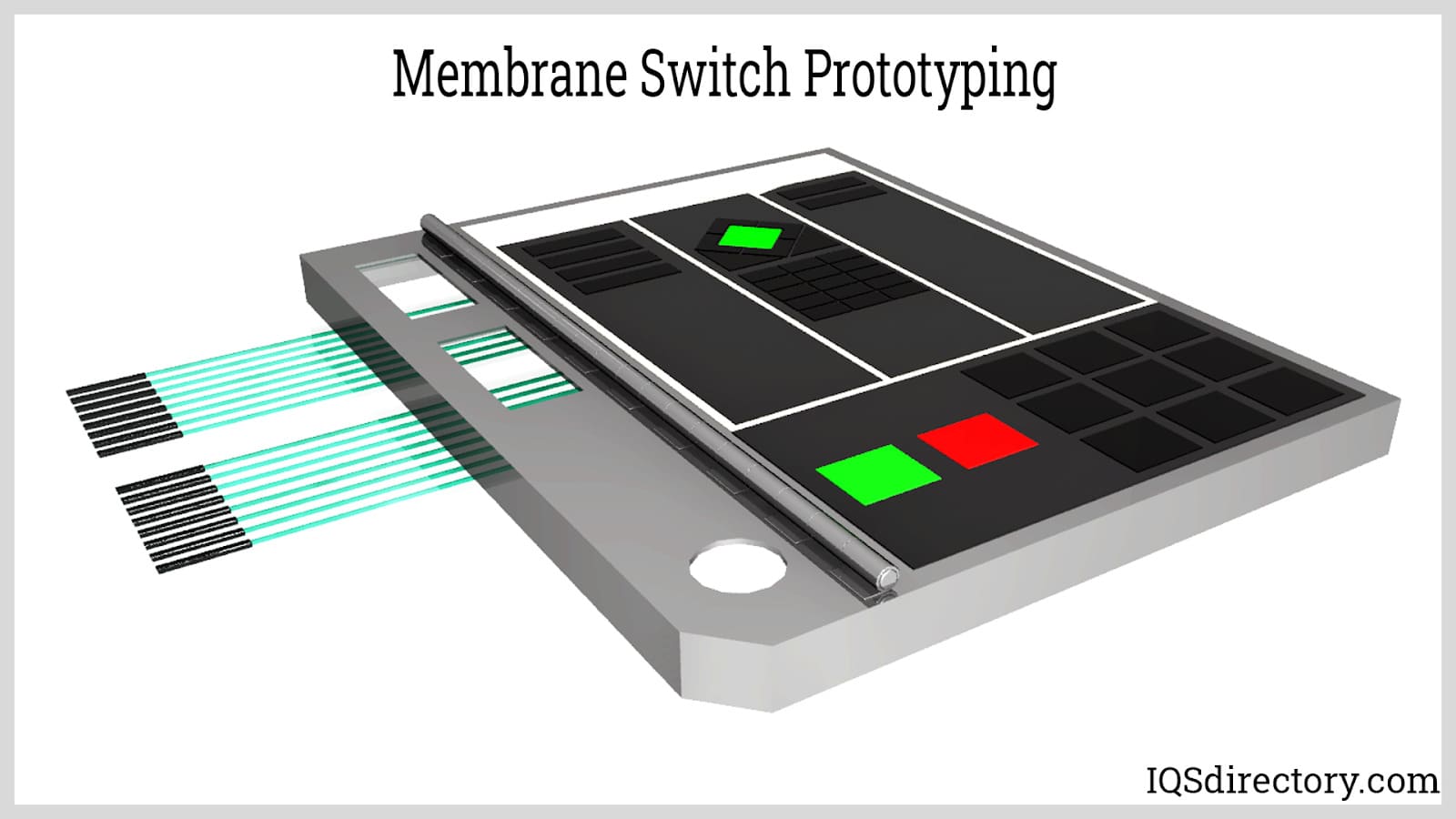

Membrane switch modern technology is a commonly utilized interface option in numerous electronic devices, providing a seamless blend of performance and style. This innovation includes numerous layers of materials, usually containing a graphic overlay, spacer layer, and a circuit layer. The graphic overlay shows the user interface aspects, while the spacer layer separates the circuit layer from the overlay till a user triggers a switch.

When pressure is related to the overlay, the circuit layer finishes the electric circuit, sending a signal to the device. This mechanism enables different arrangements, including tactile comments and backlighting choices, improving customer interaction. Membrane switches are usually manufactured making use of durable materials such as polyester or polycarbonate, making sure long life and resistance to ecological aspects like dampness and dirt.

The versatility of membrane layer switches allows their application in varied markets, consisting of clinical tools, customer electronics, and industrial controls. Their portable style permits assimilation into space-constrained environments, offering a reliable individual interface without endangering visual charm. Recognizing the ins and outs of membrane layer switch modern technology is necessary for suppliers and developers seeking to produce reliable and efficient human-machine user interfaces.

Key Advantages of Membrane Layer Switches

While various user interface remedies exist, membrane changes deal unique benefits that make them a favored selection in numerous applications. One of the main advantages is their durability; membrane layer switches are created to hold up against harsh environmental problems, consisting of dampness, dirt, and temperature level fluctuations, ensuring long-lasting performance. This durability substantially lowers the requirement for regular replacements, thereby decreasing total upkeep prices.

Moreover, membrane switches are light-weight and small, making them suitable for applications where space is limited. Their low-profile layout adds to a sleek look without endangering capability.

Cost-effectiveness is likewise a noteworthy benefit, as the production process for membrane layer changes has a tendency to be cheaper compared to standard mechanical switches. This affordability, combined with their integrity and simplicity of installation, positions membrane layer switches as a practical option for a wide variety of industries seeking efficient and effective user interfaces.

Applications Across Various Industries

Exactly how do membrane layer buttons adapt to the varied requirements of different markets? Membrane switch innovation is increasingly acknowledged for its flexibility, making it ideal for a large range of applications throughout multiple markets. In the clinical field, membrane layer buttons are utilized in analysis equipment and individual surveillance devices, where their sturdiness and convenience of cleansing are important for maintaining health criteria. The vehicle market utilizes these switches in control panels and control board, providing a structured aesthetic while making sure straightforward operation.

In consumer electronics, membrane layer buttons give a compact option for remote controls and home appliances, enhancing individual experience via instinctive design. Furthermore, the commercial industry leverages membrane layer switches for machinery control panels, gaining from their resistance to rough settings, such as wetness and dirt.

Armed forces and aerospace applications additionally make use of membrane layer buttons for their dependability and capacity to stand up to severe problems, making certain functional efficiency in vital situations. Additionally, the food and beverage industry adopts these buttons for automated systems, where hygiene and ease of operation are extremely important. Ultimately, membrane layer switches anonymous are customized to fulfill the unique demands of each industry, confirming their crucial function in contemporary technology interfaces

Layout and Modification Choices

In the realm of membrane layer button modern technology, layout and modification alternatives play an essential duty in improving capability and customer communication. These switches can be customized to satisfy certain functional demands and visual choices, making them versatile components in different applications.

Among the key customization options is the format of the switch itself, which can be made to suit distinct individual interfaces and ergonomic factors to consider. By changing the form, size, and setup of switches, manufacturers can produce intuitive designs that promote ease of usage. Additionally, the unification of various shades and visuals overlays enables branding and boosted exposure, making certain that individuals can rapidly determine functions.

Furthermore, membrane switches can be engineered with different tactile responses mechanisms, such as elevated buttons or audible clicks, to boost the user experience. Various products can additionally be selected for resilience and ecological resistance, resolving elements such as wetness, temperature variations, and chemical exposure.

Inevitably, the considerable design and modification options readily available in membrane button innovation equip organizations to develop customized options that not only fulfill useful demands yet likewise line up with their branding and operational needs.

Future Fads in Membrane Buttons

As membrane button innovation proceeds to develop, future patterns are progressively concentrated on enhancing individual experience and integrating innovative performances. One considerable fad is the combination of touch-sensitive and capacitive technologies into standard membrane layer switches. This advancement allows for even more intuitive user interfaces, giving responsive comments while maintaining a streamlined style.

An additional arising pattern is using ecologically pleasant materials, driven by the browse around this site growing demand for visit homepage lasting manufacturing techniques. Manufacturers are looking for to minimize their carbon footprint by making use of recyclable substratums and low-impact inks, aligning with global sustainability objectives.

In addition, the increase of the Web of Points (IoT) is motivating the unification of clever features right into membrane buttons. Boosted connection choices will make it possible for tools to interact with each other, enabling for smooth assimilation right into more comprehensive systems.

In addition, developments in printing technologies, such as electronic printing, are enabling higher design flexibility and customization. This enables makers to create detailed designs and dynamic shades cost-effectively.

Final Thought

In final thought, membrane layer button innovation stands for an important development in individual interface style, using significant advantages in sturdiness, customization, and cost-effectiveness. As improvements proceed to arise, specifically in touch-sensitive user interfaces and sustainable products, the possibility for membrane changes to improve individual experience and performance remains promising.

Report this page